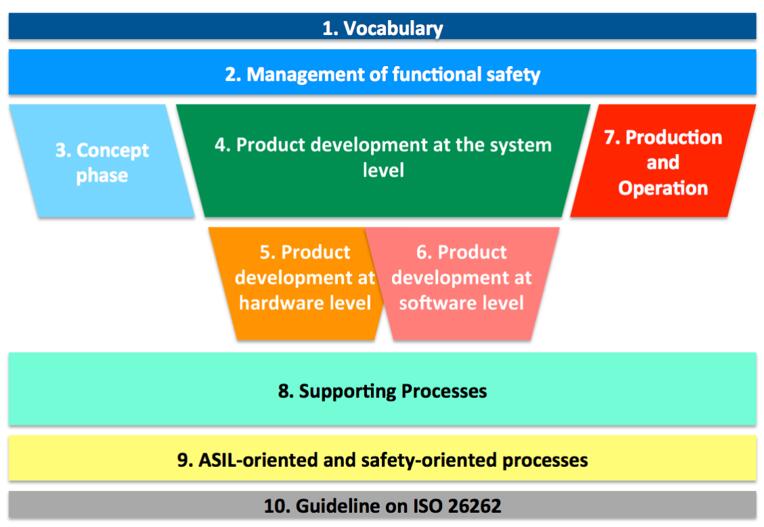

ISO26262

Overview

Introduce

IS026262, flow of workproducts visualized

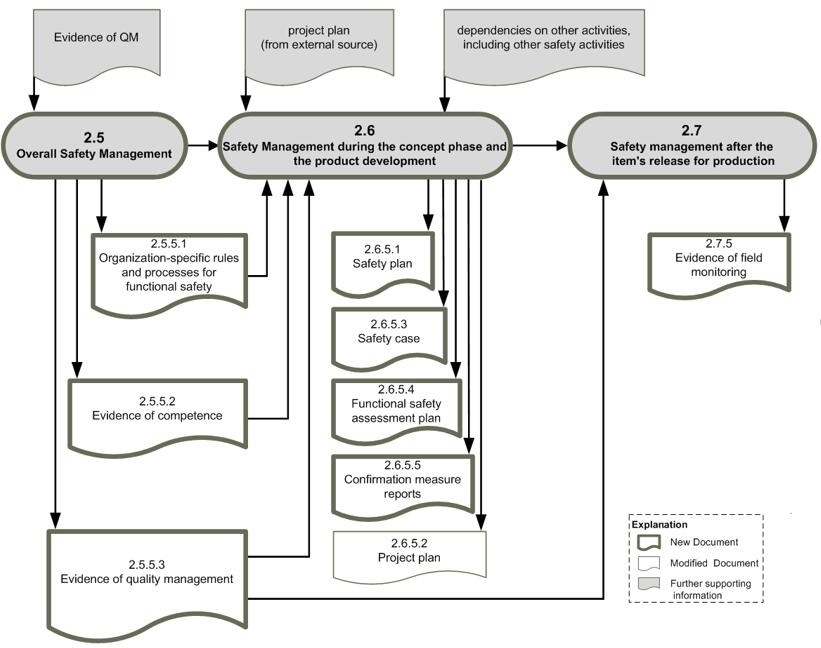

ISO26262-2, Management of functional safety, Part 2-5 to 2-7:

• 2-5: Overall Safety Management

• 2-6: Safety management during the concept phase and product development

• 2-7: Safety management after the item ́s release for production

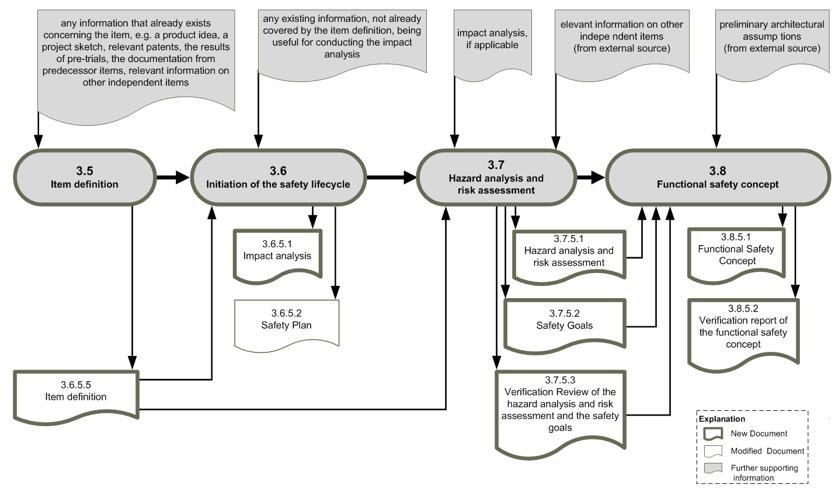

ISO26262-3, Concept phase, Part 3-5 to 3-8:

• 3-5: Item definition

• 3-6: Initiation of the safety lifecycle

• 3-7: Hazard analysis and risk assessment

• 3-8: Functional safety concept

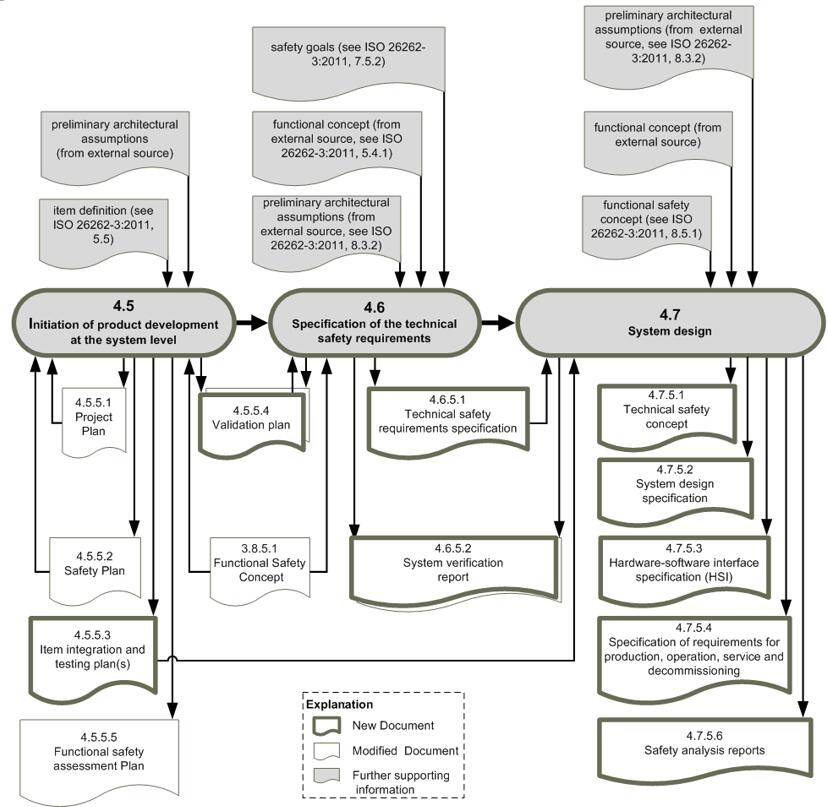

ISO26262-4, Product development at the system level (left wing), Part 4-5 to 4-7:

• 4-5: Initiation of product development at the system level

• 4-6: Specification of the technical safety requirements

• 4-7: System design

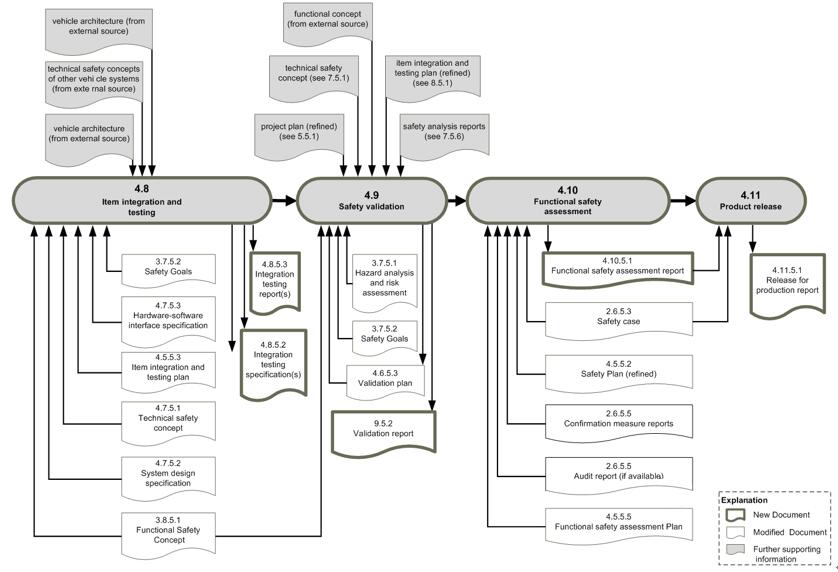

ISO26262-4, Product development at the system level (right wing), Part 4-8 to 4-11:

• 4-8: Item integration and testing

• 4-9: Safety validation

• 4-10: Functional safety assessment

• 4-11: Release for production

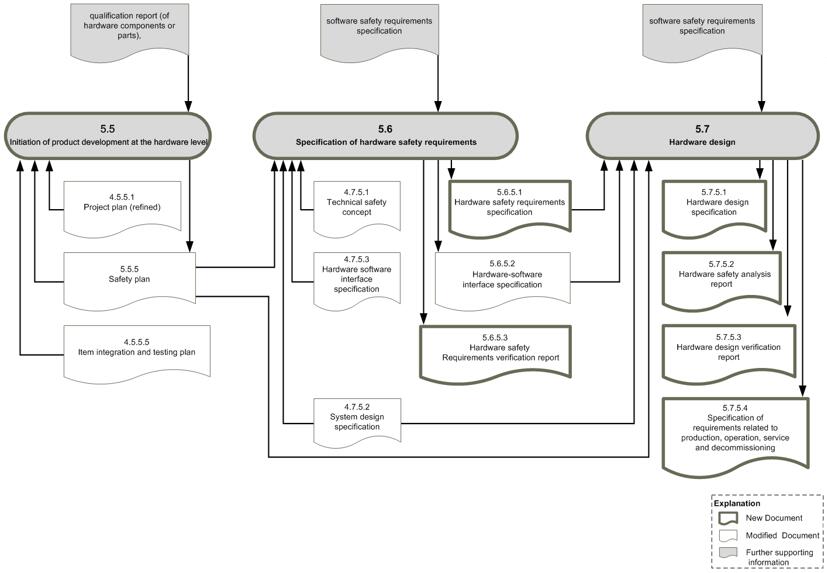

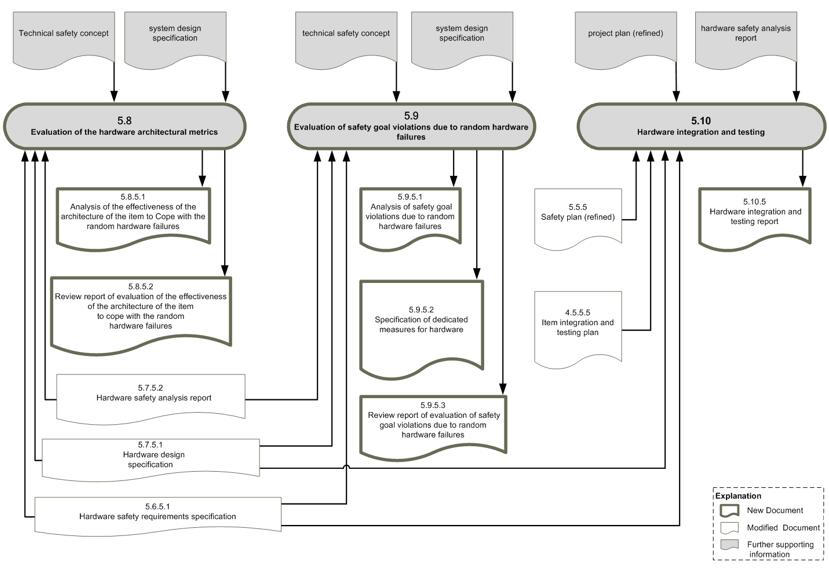

ISO26262-5, Product development at the hardware level, Part 5-5 to 5-10:

• 5-5: Initiation of product development at the hardware level

• 5-6: Specification of hardware safety requirements

• 5-7: Hardware design

• 5-8: Evaluation of the hardware architectural metrics

• 5-9: Evaluation of the safety goal violations due to random hardware failures

• 5-10: Hardware integration and testing

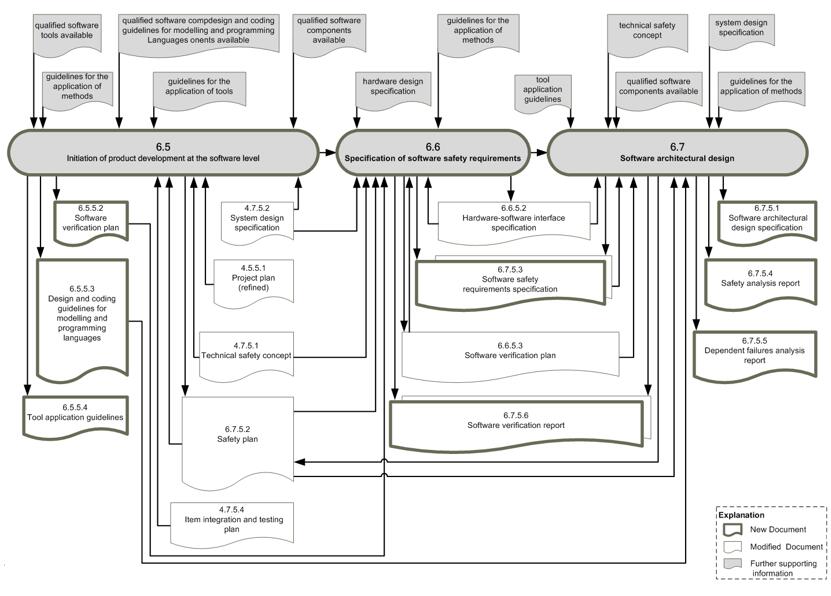

ISO26262-6, Product development at the software level, Part 6-5 to 6-11:

• 6-5: Initiation of product development at the software level

• 6-6: Specification of software safety requirements

• 6-7: Software architectural design

• 6-8: Software unit design and implementation

• 6-9: Software unit testing

• 6-10: Software integration and testing

• 6-11: Verification of software safety requirements

ISO26262-7, Production and operation, Part 7-5 to 7-6:

• 7-5: Production

• 7-6: Operation, service (maintenance and repair), and decommissioning

ISO26262-8, Supporting processes, Part 8-5 to 8-14:

• 8-5: Interfaces within distributed development

• 8-6: Specification and management of safety requirements

• 8-7: Configuration management

• 8-8: Change management

• 8-9: Verification

• 8-10: Documentation

• 8-11: Confidence in the use of software tools

• 8-12: Qualification of software components

• 8-13: Qualification of hardware components

• 8-14: Proven in use argument

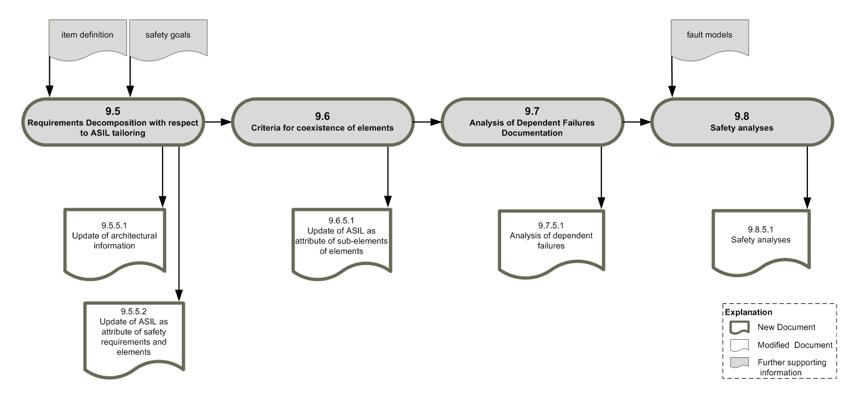

ISO26262-9, ASIL-oriented and safety-oriented analyses, Part 9-5 to 9-8:

• 9-5: Requirements decomposition with respect to ASIL tailoring

• 9-6: Criteria for coexistence of elements

• 9-7: Analysis of dependent failures

• 9-8: Safety analyses

Federated authentication

The Functional safety development process and product evaluation documents can be provided to the ISO26262 certification authority to meet the Functional safety process and product certification.

Assessment report

Conduct Functional safety development process and product evaluation on the certification subject and provide evaluation report to make the product meet the Functional safety development standard.